Solvothermal

The big thing here is beeing able to dissolve various compounds which are not dissolvable at regular conditions.

- H\(_2\)O, T>100\(^\circ\)C

- Other solvents: NH\(_3\), HF, HBr, Cl\(_2\), HCl, CO\(_2\), SO\(_4\), H\(_2\)S, CS\(_2\), C\(_2\)H\(_5\)OH +++

- NH\(_4\) is common (Ammonothermal)

- Hydrothermal:

- Crystallization of large crystals

- Synthesis of e.g. oxide powders (ex: Zeolites)

- Leaching e.g. treatment of ores

- Started 1845

- Important for big crystals of quartz

- Grown by the kilotonne in 1900

- Used for electronics, watches(oscillators), optical properties, laser windows, prisms

- Other important crystals: ZnO2, Emerald, Calcite

- Important for big crystals of quartz

Technical

- Usually more material dissolves at higher T

- H\(_2\)O with higher T:

- Ion product increases

- Viscosity decreases

- Polarity (dielectric constant) decreases (but increases with pressure)

- Synthesis usually in closed vessels

- T-P-V considerations are CRUCIAL

Two main synthesis types:

- Isothermal: powder synthesis

- T-gradient: for larger crystals

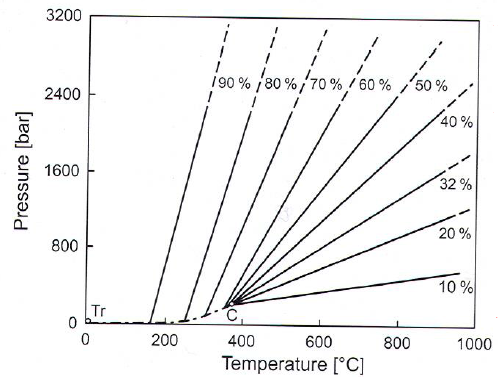

Sub vs Supercritical

- Closed autoclave -> autogeneous pressure

- H\(_2\)O above these conds is supercritical T: 374.15\(^\circ\)C, P = 220bar.

Autoclave filling

- 32% filling -> H\(_2\)O fills autoclave at T\(_c\).

- Higher filling results in full autoclave at lower T, and pressure increase.

- ex: 80% filling at 245\(^\cric\)C -> autoclave explosion

Mineralizers

- Used to increase crystallization rates

- Usually F\(^-\) or OH\(^-\) (alkali metal hydroxides, chlorides..)

- Quartz synthesis at T-gradient 400-380\(^\circ\)C at 1kbar

- Solubility too low at these temps, NaOH(or others) can be added

Retrograde solubility

- When solubility decrease at higher T.

- Can be due to properties change in solvent or compound

- Ex: SiO\(_2\) decrease in solubility over 350\(^\circ\)C as long as below 700bar.

- Also seen for halides, calcium carbonate ..

Hydrothermal

Advantages:

- Moderate T (100-300\(^\circ\)C) subcritically at autogeneous pressures.

- Possible to synthesise materials below transformation temperatures (\(\alpha\)-CuI @ 390\(^\circ\)C, \(\alpha-\beta\) transition for Quartz @ 580\(^\circ\)C)

- Transition metals can be made with unusual ox-states (CrO\(_2\))

- Prep of metastable phases (GeO\(_2\) with Quarts structure using Quarts seed)

- Formation of Zeolites + other microporous materials

- Usually dissolution/Precipitation mechanisms

Leaching:

- Bayer process -> extract high-grade Al(OH)\(_3\) from bauxite ore

- Hydrothermal extraction w/dense NaOH solution via reaction to soluble aluminate complex(NaAl(OH)\(_4\))

- Al(OH)\(_3\) precipitated by cooling, diluting and seeding

- Heated to corundum for Al metal production.

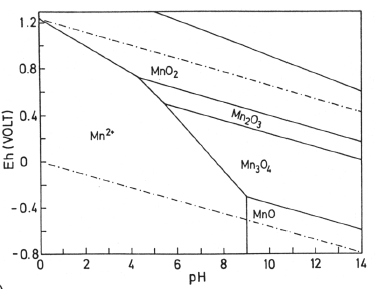

Eh-Ph diagrams

- Ox state can be controlled by pH and V.

- Diagrams change with T and P

- Lines pushed down and left at higher T

- Lines pushed down and left at higher T

Buffers: Used to control the potential to ensure spesific ox-states. Hydrogen permeable membranes can be used. CuO can buffer to ensure Fe\(^{2+}\) is not made.

Setups

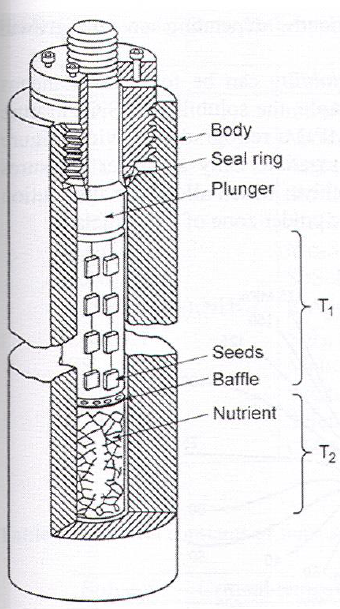

Synthesis in T-gradient

- Nutrient (polycrystalline powder of precursor) placed in bottom

- Baffle (perforated disc) separates dissolution and growth zones and reduces particle flow

- T\(_1\)< T\(_2\) -> convection to transport hot L to GrowthZone.

- Required: some wt% solubility 0.001-0.1wt% sol diff over 10

Autoclaves

- Open and closed vessels

- Morey: Closed, up to 400\(^\circ\)C, 400 bar, simple, autogeneous

- Tuttle: “Cold seal” outside oven, may be watercooled. Pressure from external source, up to 1100\(^\circ\)C, 5000bar.