Porosity

- Classically organics, polymeric foams

- Inorganic porous materials developed for:

- Insulation (Porosity#Metallic Foams)

- Cushioning

- Impact protection (Porosity#Metallic Foams)

- Catalysys (Porosity#Zeolites)

- Membranes (Porosity#Metallic Foams)

- Construction

- nm-mm pore sizes

- Ordered and irregular structures

- Chemical compositions (metals, oxides)

- Different preparative approaches.

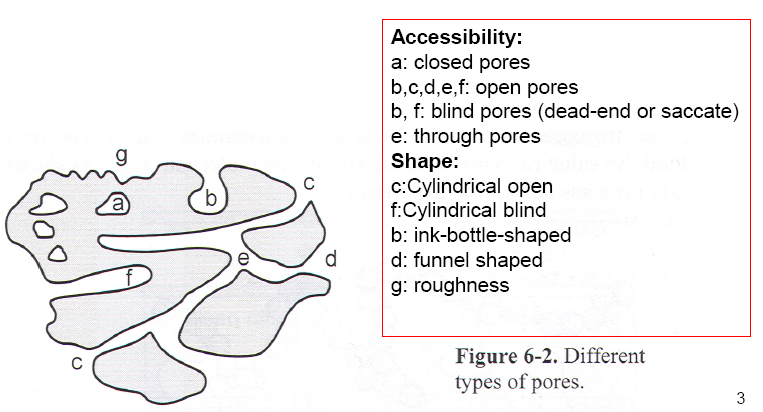

Definitions:

- True, apparent and bulk density

- Pore volume, V\(_p\)

- Pore size, (width, diameter)

- Porosity = V\(_p\)/V, V = apparent volume

- Surface area: Accessible area of solid surface per unit mass.

Measuring:

- Depends on method/material

- Coastline paradox

- Surface probing w/molecules

- Bulk probing (Spectroscopy, diffraction, scattering)

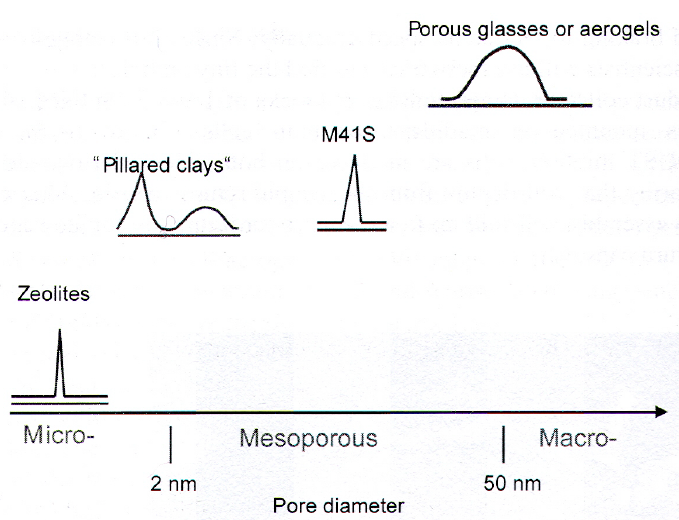

Size regimes:

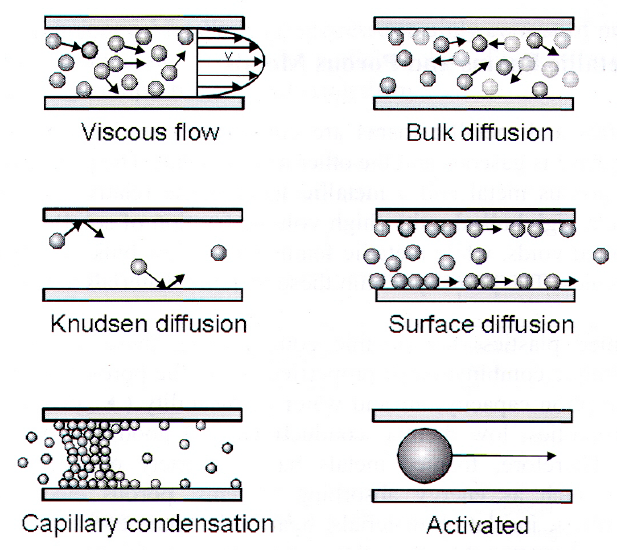

- Microporoes: <2nm ~ molecules: activated transport

- Mesopores: 2<r<50nm (or < Mean Free Path)

- Knudsen or surface diffusion, capillary, condensation or multilayer adsorbtion.

- Macropores: >50nm (or >MFP), Bulk diffusion + Viscous flow.

Types: Porosity#Metallic Foams Porosity#Aerogels Porosity#Zeolites Porosity#MOFs Porosity#MCMs

Metallic Foams

- Composite of gaseous and solid phases.

- Porous metals: High bulk density, independently distributed voids

- Metallic Foams: Low bulk density, connected voids

- Porosity: 30-90 vol%

- Uses:

- Impact absorbtion

- Air + water permeability (Filtering, membrane)

- Acoustic properties (sound absorbers)

- Low T conductivity (Insulation)

- Surface area (Porous electrodes, heat exchanger)

- electromagnetic shielding

Synthesis methods

- Casting:

- Foaming: decomposition to gas while mixing and cooling->high porosity

- Lost-Foam: Open porous polymer foam -> filled with inorganic(eg gypsum) -> pyrolysis of polymer foam -> fill with molten metal -> Remove mold (eg solvation) -> product w/open porosity, roughly same as start polymer

- Infiltration: pour molten metal in cast, egt NaCl beads which is then dissolved.

- Gas-eutectic: insert often H in metal, cool down from one side through eutectic composition-> gas is formed as metal solidifies. Often gives gas-rods in metal.

- Powder metallurgy: Pack mold with powder(or fibres) -> sinter together.

- Deposition: CVD, electrochemical, PVD: deposit on prous organics.

Aerogels

Supercritical drying of gel.

- Mesoporous (2<r<50nm)

- bulk densities: 0.004-0.5g/cm\(^3\)

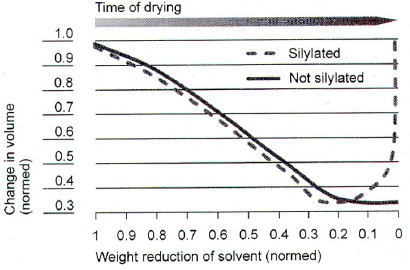

Ambient pressure drying

- Collapse caused by capillary forces, fixed by:

- Strengthen network

- Modify contact angle (solid-liquid)

- Exchange water with waterfree solvent

- Silylate Si-OH-group -> springback

Zeolites

- Porous, hydrated aluminosilicates

- Natural or synthetic

- \(M^n_{x/n} Si_{1-x} Al_x O_2 \cdot yH_2O\)

- Counter ions compensate charge from Al substitution

- Usually mobile and in pores

- Zeolitic water to measure porosity (removed by heat)

- Loewensteins rule: Only 0.5 of Si can be exchanged for Al (both extremes exist)(Al-O-Al bonds not allowed)

Zeolite Usages:

- Molecular sieves: discrete pore sizes allowing special molecules.

- Ion exchange: Counter cations can move and may be exchanged. Used in detergents, waste water purification, pigs food.

- Catalysis: Heterogeneous cat for petrochem. Zeolite largest use: Cracking catalyst (faujasite). Production of synthetic gasoline from methanol. Tuned by Si/Al ratio, chemistry and counter ions.

Zeolite Synthesis

- Deville: Lab scale: K\(_2\)Si\(_2\)O\(_5\) + NaAlO\(_2\) in glass ampoule

- Usually made from sol or gel in mild hydrothermal conditions (<350\(^\circ\)C)

- Ingredients: H\(_2\)O, Si-source, Al-source, pH-regulators, templates.

- Templating: Cations working as counter-ions also work as templates: modifying cell and filling void

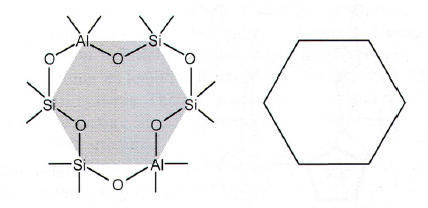

Zeotype Structure

- BBU: Basic building unit: the tetrahedron: They all share corners and have periodic structure

- CBU: Composite building units: polymeric structures with rings and prisms

- Tertiari building units: larger cases

Microporous, zeolite-like structures

- Aluminophosphates: AlPO4

- Si-doped SAPO

- Metal doped MePO

MOFs

Metal organic frameworks

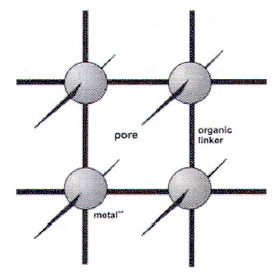

MOF Structure

Built by BBU’s consisting of metallic connectors and organic linkers.  However, unlinke Porosity#Zeotype Structure, connector-linker bonds are coordinative or ionic, not covalent.

However, unlinke Porosity#Zeotype Structure, connector-linker bonds are coordinative or ionic, not covalent.

- Among the largest pores of crystalline structures.

- >1000 m\(^2\)/g surface area

Classification

- 1st gen: Collapse upon guest / template removal

- 2nd gen: Stable + robust, porous after guest removed.

- 3rd gen: Flexible + dynamic, responds to external stimuli.

- The last two can be used for gas storage or catalysts.

MOF Synthesis

- Standard coordination chemistry methods are used

- Metal ions are reacted with organic ligand

- Low T, solvothermal synthesis

- Products determined by thermodynamics, not kinetics

- Linker flexibility important for properties (Usually rigid)

- Flexible linker may allow several structures leading to poor crystallinity.

- Self assembly of BBUs

- Initially, pores are filled with guest template molecules, which are hard to remove due to MOF’s low thermal stability.

MCMs

Mobil Crystalline Material Mobil Composition of Matter

MCM Structure

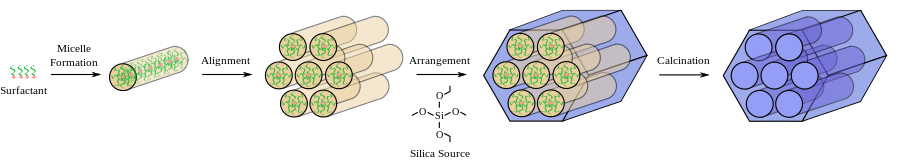

- Mesoporous (2<r<50nm) material from supramolecular species(eg micelles) (Not ions or organics) In reality 2-10nm

- Amphiphilic surfactant molecules

- Amorphous pore walls

- Narrow pore size distribution

MCM Synthesis

Solvothermal#Hydrothermal synthesis: Water, amphophilic molecule(eg CTAB), soluble inorganic + catalyst

- Form supramolecular arrangement of molecules (Hydrophilic head, hydrophobic tail)

- Templating (They form tubes, 3d or lamellar with increasing consentration of CTAB). Either infused with Silicon, or silicon already on amphophilic molecule.

- Remove template ( By solvent extraction, calcination, O\(_2\) Plasma, Supercritical drying) Only hexagonal or 3d structures can survive this.

MCM Usage

MCM-41 used as Catalyst, catalyst support, adsorbent, host for nanomaterials

Opals

Produced by packing of solid material template Template requirements:

- Must be removable

- Must be compatible with process conditions

- Precursor solution must wet the template

- Must have narrow size distribution.

Two synthesis routes:

- Stöber process: 50nm-2mm

- Organic polymer spheres produced from emulsion polymerization.