Nanostructures

- Properties depend on chemistry and arrangement of building blocks in 3D

- Size matters! Metals conduct, not NP metals.

- Bonds->orbitals: Particle in box

- Surface/interface effects: High % of atoms are on surface (5nm=50%surface atoms)

- Nanocrystalline

- Grains in nanosize: (ex: NP Pt 400% more catalytic)

- Network of intercrystalline regions

- Nanocomposites: NP’s in matrix

- Metal-NP’s composites as heterogenes catalyst

- Semiconductor (Q-dots)

- Nanofibres in ceramic matrices

- Ex: Damascus sabre: CNT NP’s

Nanocrystalline ceramics

Regular ceramics typically 10\(\mu\)m grains. Nano:

- 10-100nm grains

- 3nm grains -> 75% in interphase

- Interphase density only 60-70% of bulk

- Not equilibrium state

- Used as catalyst of oxides

Diffusion/Sintering

Densifiable by sintering at lower temps.

- High surface energy

- Short diffusion lengths

- Low stability of interphase region Doped more efficiently at low T

Hardness/Strength

- Are higher for NP’s than regular.

- Superplasticity: Can undergo deformation without fracture.

- Not yet proven for low Temp

- Can become ductile.

Gold/Silver NP’s

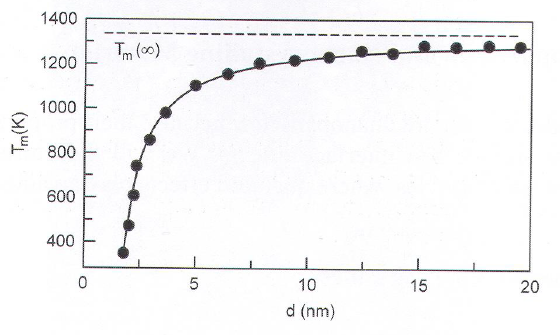

Melting

Happens at lower T with smaller NP size.

Au-catalyst

- Makes CO\(_2\) of CO.

- NP > 10nm -> no effect

- < 5nm, hemispherical -> effective

- < 2nm, dependent on atom amount

- Cubo-octahedron: Low activity

- Icosahedron: High activity