Aerosol

Gas phase powder synthesis

- Does NOT involve large volumes of liquid (compared to wet process)

- Timescale is very short

- High: Purity, yield, throughput

- Multicomponent + nanophase materials possible

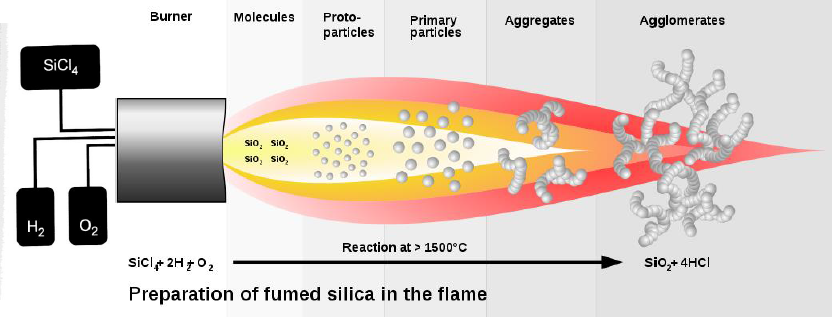

- Flame hydrolysis:

- 2H\(_2\) + O\(_2\) -> H\(_2\)O

- SiCl\(_4\) + 2H\(_2\)O -> SiO\(_2\) + 4HCl

Aerosil

- Degussa, 1942

Product:

7-40nm particles

Surface area: 50-400m^2/g, S = 6/(d*r) (surface, not pores)

200L \(\approx\) 10kg

Fumed titania also produced (as pigments)

Process routes

Terms:

Coagulation: Attachments of two particles when they collide

Coalescence: Fusion (sintering) of two particles

Agglomerates: Assemblies of primary particles physically held together by weak interactions (soft agglomerates)

Aggregates: Assemblies of primary particles hed together by stronger forces (Hard agglomerates)

Precursors often similar to what used in CVD/PVD

Two main processes:

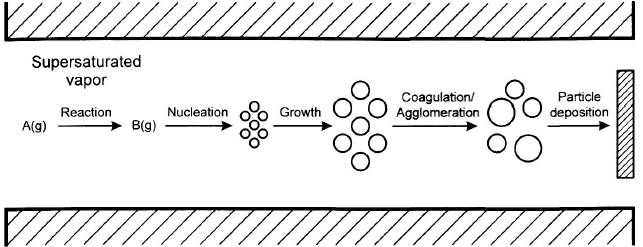

Gas to particle conversion

- High T reaction between gases

- Homogeneous gas phase reactions. Formation of molecular or cluster compounds

- Nucleation formed from supersaturated vapour. Homogeneous nucleation from molecules or clusters.

- Particle growth, by several mechanisms: Condensation, surface reactions, coagulation. The relative rates of particle collision, coalescence and sintering are important for the shape of the obtained particles.

- Precursors: all from CVD#Precursors + more reactive ones.

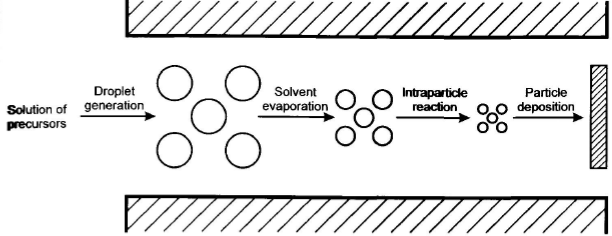

Spray Pyrolysis

- Sol or slurry atomized and pass through heated area

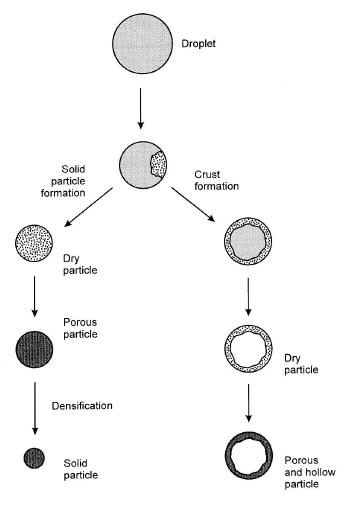

- Solvents evaporate, particles pyrolyse or react to form particles.

- Often hollow spheres are formed

- Particle size depends on size of droplets and concentration

- Porosity controlled by concentration and thermal profile

Three types of reactors: Flame Reactor:(Flame pyrolysis) Combustion reaction to heat spray. Short residence time, max use of energy. Risk of contamination by combustion reactants.

Heating Reactor: Spray into hot furnace. Good control of: T + residence time. Growth on walls, formation of hard aggregates.

LASER Reactors: Heated by laser; efficient transfer of heat to gas. Plasma reactors. Precursors: solution from sol-gel -> atomic mixing.

Film deposition

- Spray pyrolisys (droplet deposition)

- Evaporation of substrate

- Aerosol Assisted CVD (AACVD)

- Up to 5\(\mu\)m/min particle deposition

- 1-5\(\mu\)m/min typically

Products

Large scale: Titania, silica, Al-powder(From chlorides by flame pyrolisys)

Smaller scale: Bi\(_2\)O\(_3\), Cr\(_2\)O\(_3\), Fe\(_2\)O\(_3\), GeO\(_2\), NiO, MoO\(_2\), SnO\(_2\), V\(_2\)O\(_5\), WO\(_3\), ZrO\(_2\), AlBO\(_3\), Al\(_2\)TiO\(_5\), AlPO\(_4\)

Metal Synthesis: Fumed silica particles: SiCl\(_4\)(g) + 4Na(g) -> Si + 4NaCl.

Niobium metal particles: 2NbCl\(_5\)(g) + 5Mg -> 2Nb + 5MgCl\(_2\)